You know the compressor is always leaking air as when you shut it down with a full charge of air in the tank after a short while you can see that the tank pressure gauge display is showing that the tank pressure is dropping.

Air compressor causing crankcase pressure.

See figure air line attachments.

To try and find the leak do the following.

Many times oil will be noticed in both the compressor housing and the turbine housing with this type of problem.

H 2 o 0 75 kpa check the air compressor.

To determine if a defective air compressor is causing excessive crankcase pressure perform the following.

The solution is to pull the oil fill tube cover and make sure that the vent in.

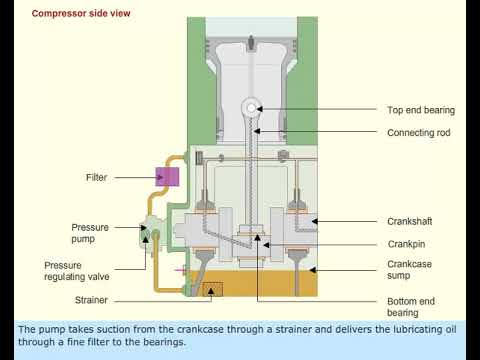

Another problem is low engine oil or low oil pressure.

Refer to 15 4 10 1 crankcase pressure test.

When this happens the connecting rod bearing furthest from the oil supply line will be the one that burns out from lack of lubrication.

The compressor builds up pressure in the head until the connecting rod breaks usually coming out the side of the compressor crankcase.

Repeat step and record the test results.

Realign motor pulley with compressor flywheel.

Disconnect the air outlet line from the air compressor.

When excessive air pressure is coming from the crankcase the oil is actually being pushed past the seals.

If the engine crankcase pressure is less than 3 in.

Soon if the air compressor is plugged in the pressure switch will react to the falling tank pressure and start the.

Perform a crankcase pressure test and record the test results.

If you plug in the compressor the pressure switch response to the air leak and dropping compressor pressure will be to start the compressor again.

Perform a crankcase pressure test.

Compare the results of test one with test two.

I have replaced crankcase seal and it s still building air pressure in the crankcase and blowing the seal.

Improper mounting a further cause of.

Disassemble check valve assembly clean or replace faulty parts.

Receiver does not hold pressure when compressor is unloaded.

To determine if a defective air compressor is causing excessive crankcase pressure perform the following perform a crankcase pressure test and record the test results.

Check to see whether the crankcase needs new oil or bearings or if it needs to be replaced outright.

Limit air usage to compressor capacity by using fewer or smaller tools.

I have a craftsman air compressor model 919 184170.

To determine if an obstructed or damaged breather is causing excessive crankcase pressure perform the following.

If you suspect crankcase failure a good place to start is by inspecting the engine s crankcase.

Disconnect the air discharge line from the air compressor.

If the engine crankcase pressure is greater than 3 in.

Clarke rebel 30 air compressors pressure buildup in crankcase of rebel compressor by.

H 2 o 0 75 kpa replace wire mesh element.